Benefits and Applications of Conveyor LBP Chain

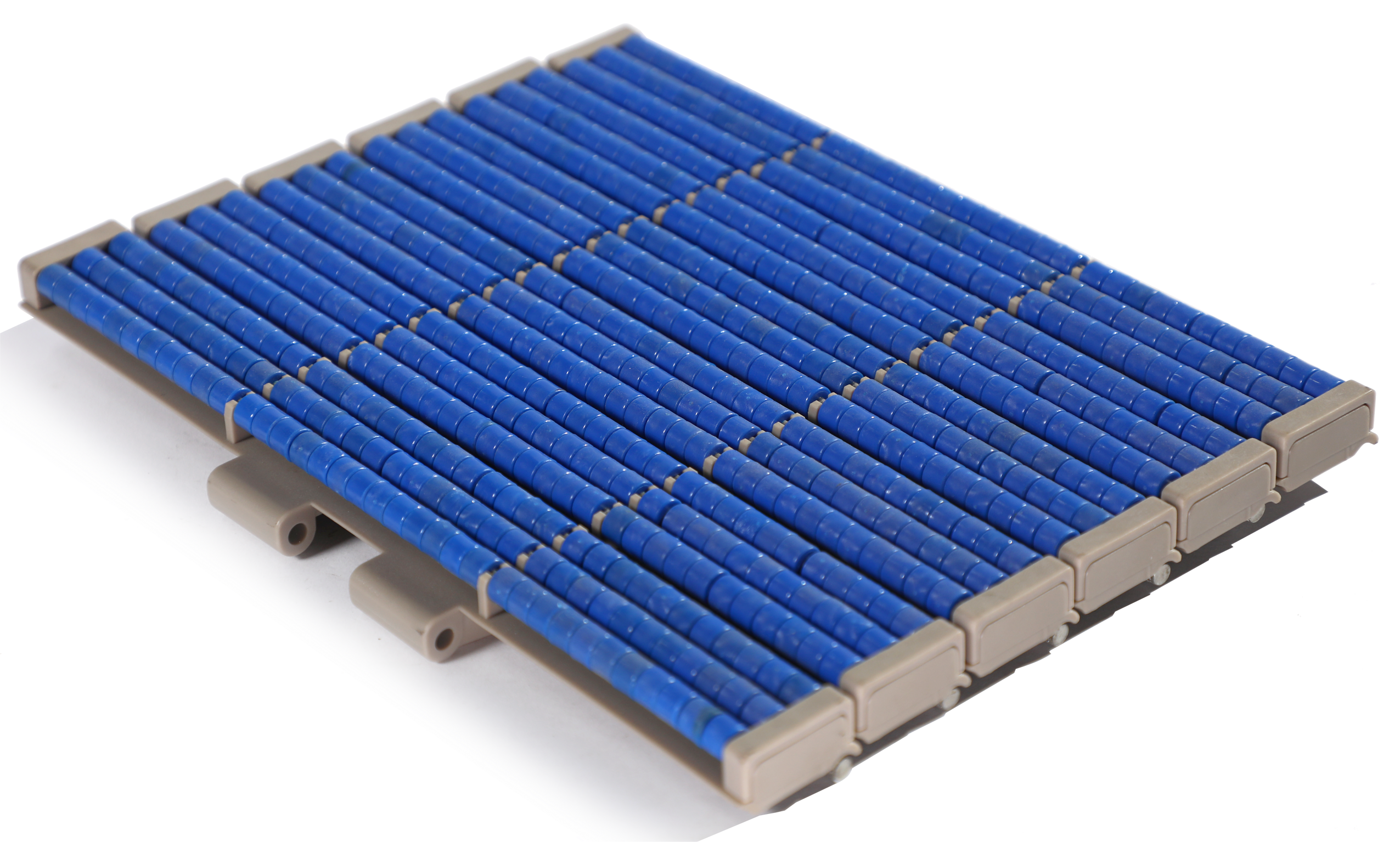

Conveyor LBP chains are advanced solutions engineered for enhancing material handling processes across multiple sectors. These unique chains effectively reduce back pressure, ensuring the seamless and reliable movement of products, even in fast-paced working environments.

Key Features of Conveyor LBP Chain

Low Back Pressure Technology

The innovative design of the LBP chain significantly reduces friction between transported items. This characteristic is vital in mitigating damage risk and ensuring smooth operational flow.

Durable Construction

Constructed from high-grade materials, LBP chains are designed to support heavy loads and endure significant wear, offering impressive longevity in performance.

Modular Design

The modular nature of LBP chains facilitates straightforward customization and integration within existing conveyor setups.

Enhanced Product Stability

These chains are specifically designed to maximize stability during transport, preventing items from tipping or moving unexpectedly.

Applications of Conveyor LBP Chain

Food and Beverage Industry

LBP chains find extensive application in the food and beverage industry, ensuring the efficient transport of bottles, cans, and other products, which minimizes downtime and boosts productivity.

Pharmaceutical Industry

These chains are particularly advantageous in pharmaceutical manufacturing, as they are adept at handling delicate materials with precision and care.

Additional reading:Valve for high pressure, high viscosity, highly abrasive ...

Automotive Industry

In automotive assembly lines, LBP chains enhance the movement of components, improving efficiency and ensuring consistent workflow.

Packaging Industry

These chains are ideal for packaging operations, providing secure transport of cartons and boxes without risking product damage.

Benefits of Using Conveyor LBP Chain

Reduced Maintenance Costs

The sturdy design of Radius LBP chains is intended to cut down on wear and prevent frequent maintenance, which in turn lowers replacement costs.

Improved Operational Efficiency

Thanks to low back pressure and increased stability, LBP chains enhance workflow fluidity and speed up processing times.

Versatile Applications

Suitable for a multitude of tasks from food processing to heavy industrial applications, these chains adapt excellently to a variety of operational requirements.

Product Safety

By minimizing back pressure, LBP chains safeguard items from damage, thus upholding high-quality standards throughout the transport process.

Conclusion

Conveyor LBP chains are critical for efficient material handling in numerous sectors. Their innovative features, robustness, and flexibility render them a strategic investment for enhancing productivity and ensuring product safety. Incorporating LBP chains into your processes can lead to improved operational workflows and overall efficiency.

Previous: A Guide to Progressive Die Stamping

Next: Valve for high pressure , high viscosity, highly abrasive ...

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments

0